Updated 2/20/18 - Photos added from 2006

Layout Progress - 1st Decade

Andy and Charlie want to thank everyone who has helped over the years for their hard work and dedication to the PML. From left: Bruce Light, Tom Gaus, Greg Cinna, Bob Dengler and Gary Gillespie. And to those not pictured Bob Evans, Jerry Kyslinger, Paul Metzger, Kent Miller, Dan Grieco, Jim Montgomery, Howard Heltman, Mike Rabbit, Kevin Sapanara and Patrick Altdorfer. Thanks for Everything!

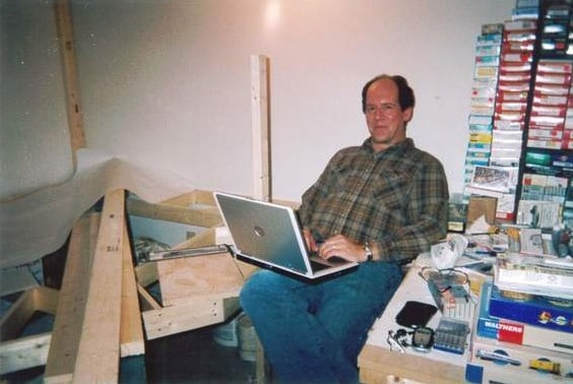

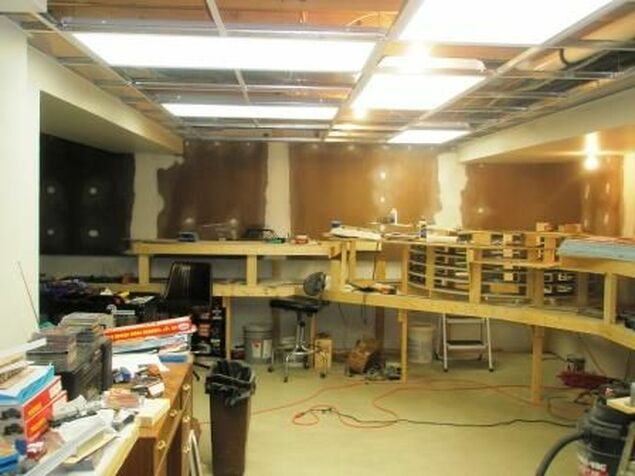

My father built my brother and me an HO scale train layout when I was a child, and I enjoyed detailing the simple 4 x 8 foot layout until my early teens. After graduating from college and having my railroad interest reawakened, I dug out this layout and bought some up-to-date motive power and rolling stock. Night school, my career and a relocation sidelined model railroading for most of a decade, but in 1999 I discovered that several of my co-workers in the civil engineering profession were also modelers and we had the nucleus to plan and build a model railroad in my basement. We joined the local division of the NMRA (Mid-Central Region, Keystone Division 2), which gave us an opportunity to visit a number of local club and home layouts, many of which provided us with ideas and inspiration.

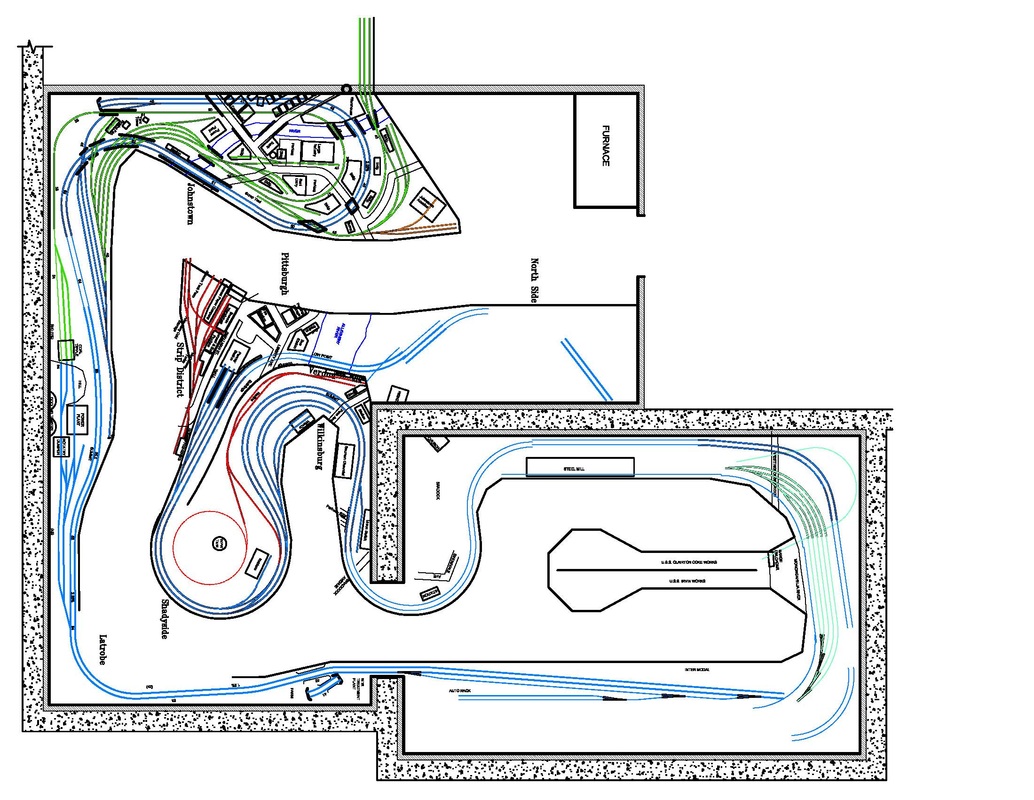

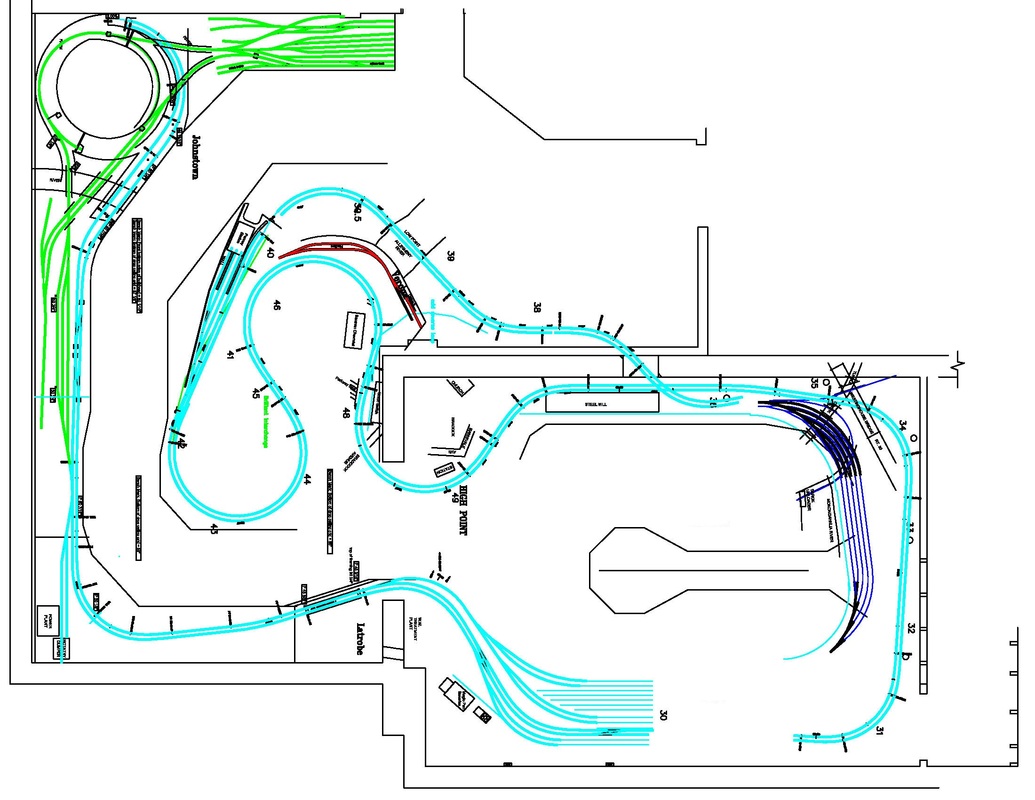

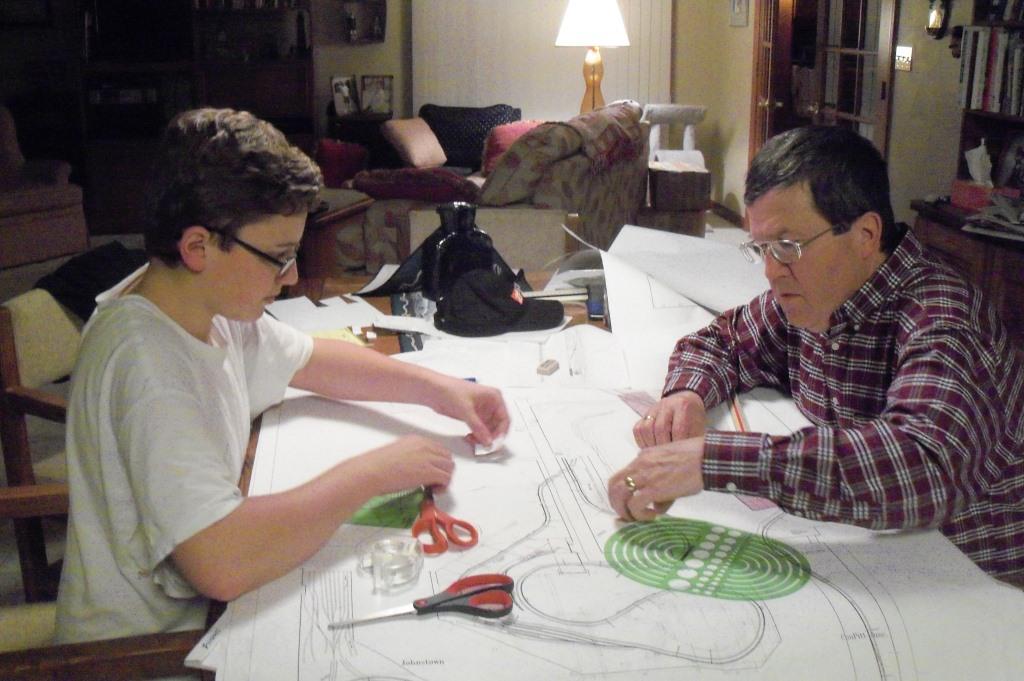

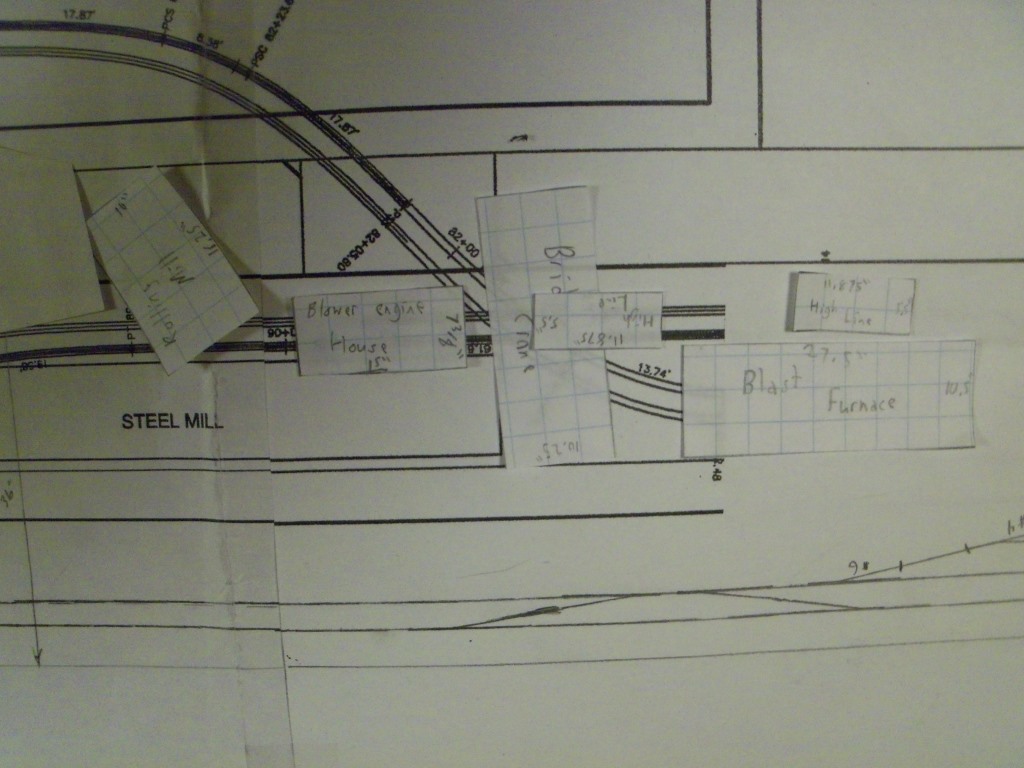

I began planning a layout using a scale drawing of the basement (1 inch = 1 foot), which was a good size for sketching and allowed the use of an HO scale track planning template purchased at a local hobby shop. My initial goal was to model the Conrail main line from Wilkinsburg to Pitcairn, the area that I had known as a boy. However, after operating on several home layouts in our area (Ken Hanawalt and Carl Volkwein’s Turtle Creek Railroad; Bob Prehoda’s Huntingdon Northern; and John Scott’s Johnstown, Maryannville and Scottdale), I soon realized that realistic operations required a point of origin and a destination for freight traffic, some of which might even be off the layout. My attempt to model one stretch of track as I had originally planned would severely restrict realistic operations. I needed to “think big” and use selective compression in order to model an entire division, rather than just a few towns.

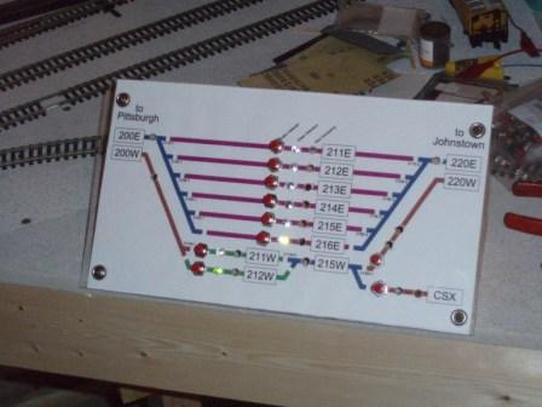

My next layout sketch went further – Wilkinsburg to Latrobe. However, through an addition to our home, our real estate agents were able to acquire additional right-of-way in the basement and “real world” operations still dictated a larger area to be modeled. There are no significant interchange points on the Conrail main line between Greensburg and Latrobe, so I reached further east and decided that Johnstown should be the eastern-most city modeled on the layout. This would allow an interchange with the Chessie System (now CSX) at Johnstown. The two areas dedicated to the layout measure roughly 16’ x 20’ and 13’ x 25’, together forming an “L”. A small area under the stairs can serve as a dispatch office.

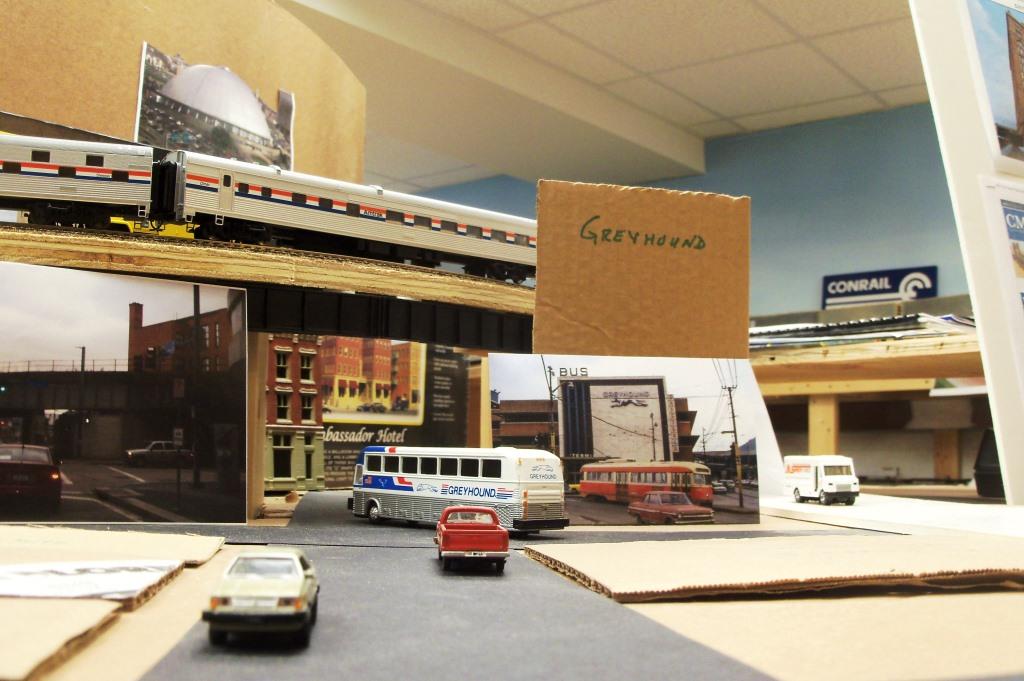

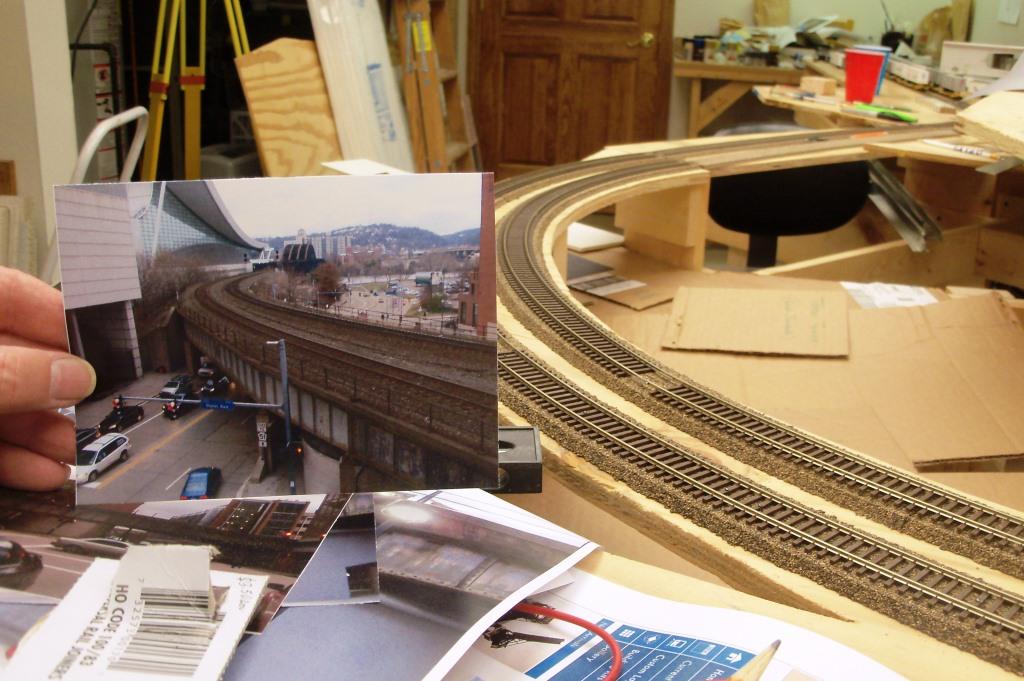

Looking towards the western end of the layout, again there are no significant interchange points at or near Wilkinsburg, so it was decided to extend the layout west to include downtown Pittsburgh and a bit beyond. This gives us the opportunity to model a bit of urban scenery, which I enjoy, including the magnificent Pennsylvania Railroad Station in downtown Pittsburgh. While I would have loved to model Conway Yard, located perhaps 20 miles northwest of Pittsburgh, I could not do it justice given my space constraints. Instead, the layout will terminate at its western end at Island Avenue Yard, a smaller interchange yard located on Pittsburgh’s North Side. Although not as busy as it was in the glory days of the Pennsylvania Railroad, Island Avenue Yard today serves as the interchange point with the Allegheny Valley Railroad.

I began planning a layout using a scale drawing of the basement (1 inch = 1 foot), which was a good size for sketching and allowed the use of an HO scale track planning template purchased at a local hobby shop. My initial goal was to model the Conrail main line from Wilkinsburg to Pitcairn, the area that I had known as a boy. However, after operating on several home layouts in our area (Ken Hanawalt and Carl Volkwein’s Turtle Creek Railroad; Bob Prehoda’s Huntingdon Northern; and John Scott’s Johnstown, Maryannville and Scottdale), I soon realized that realistic operations required a point of origin and a destination for freight traffic, some of which might even be off the layout. My attempt to model one stretch of track as I had originally planned would severely restrict realistic operations. I needed to “think big” and use selective compression in order to model an entire division, rather than just a few towns.

My next layout sketch went further – Wilkinsburg to Latrobe. However, through an addition to our home, our real estate agents were able to acquire additional right-of-way in the basement and “real world” operations still dictated a larger area to be modeled. There are no significant interchange points on the Conrail main line between Greensburg and Latrobe, so I reached further east and decided that Johnstown should be the eastern-most city modeled on the layout. This would allow an interchange with the Chessie System (now CSX) at Johnstown. The two areas dedicated to the layout measure roughly 16’ x 20’ and 13’ x 25’, together forming an “L”. A small area under the stairs can serve as a dispatch office.

Looking towards the western end of the layout, again there are no significant interchange points at or near Wilkinsburg, so it was decided to extend the layout west to include downtown Pittsburgh and a bit beyond. This gives us the opportunity to model a bit of urban scenery, which I enjoy, including the magnificent Pennsylvania Railroad Station in downtown Pittsburgh. While I would have loved to model Conway Yard, located perhaps 20 miles northwest of Pittsburgh, I could not do it justice given my space constraints. Instead, the layout will terminate at its western end at Island Avenue Yard, a smaller interchange yard located on Pittsburgh’s North Side. Although not as busy as it was in the glory days of the Pennsylvania Railroad, Island Avenue Yard today serves as the interchange point with the Allegheny Valley Railroad.

2006

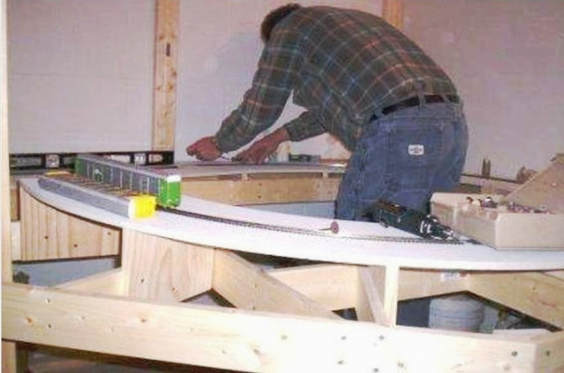

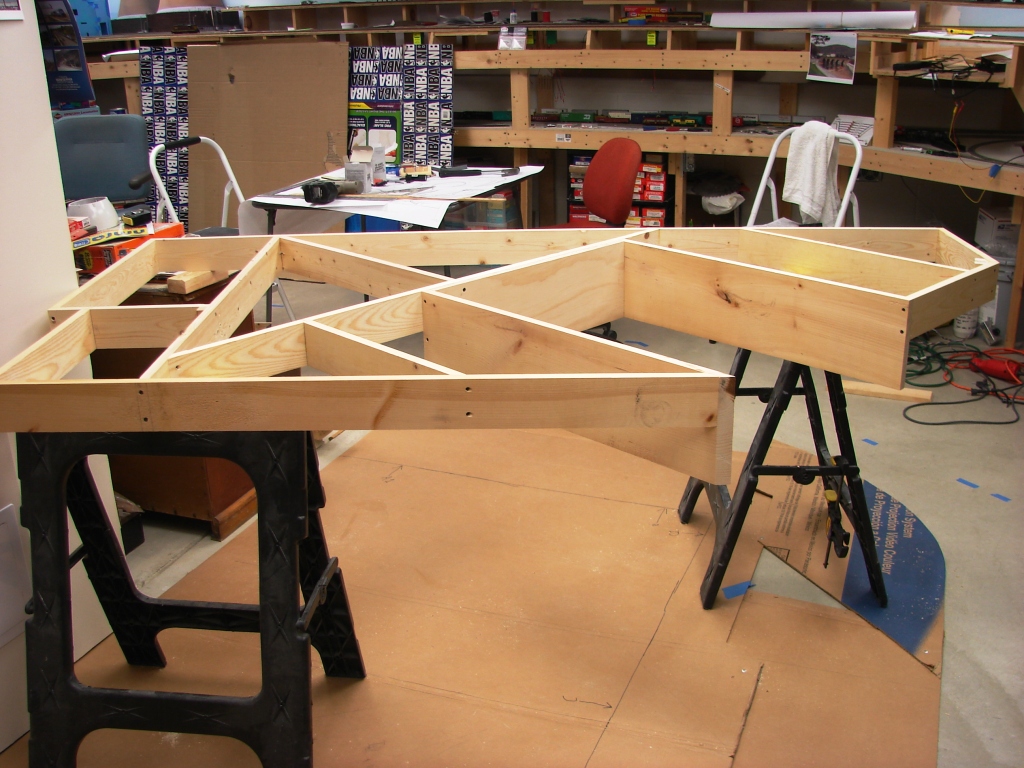

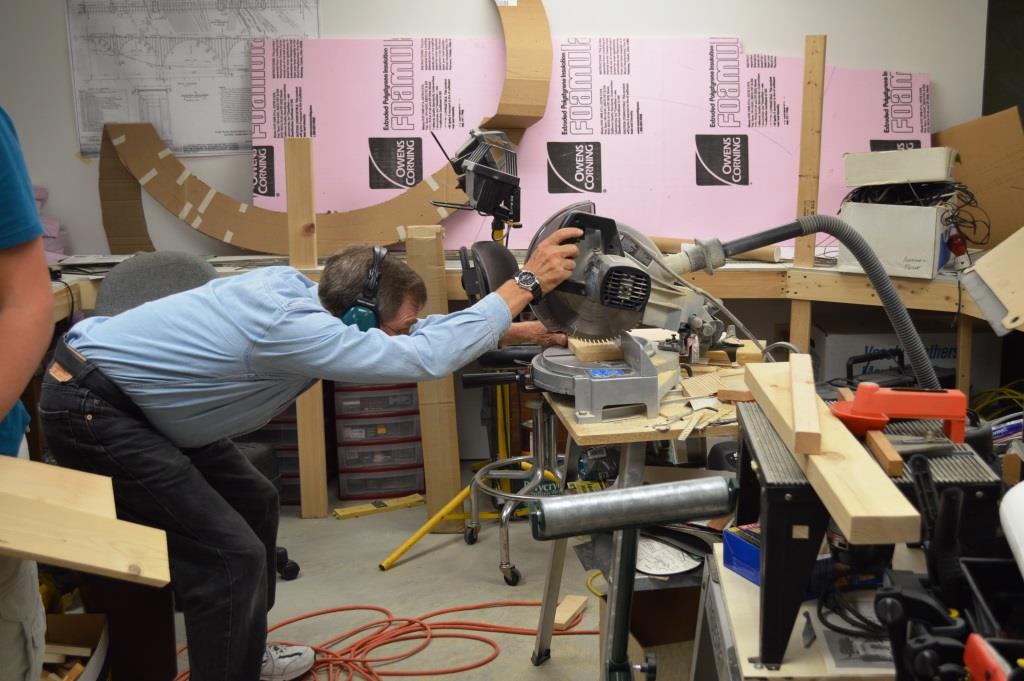

In 2006 construction was started on the helix, a 4.5 revolution spiral to get to the second level. Working one night a month, the helix took about a year to complete because everything had to be just right on the first level in order for the rest to work out.

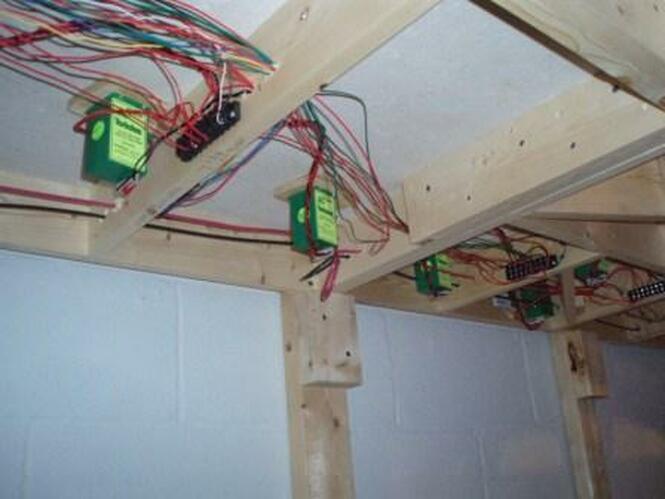

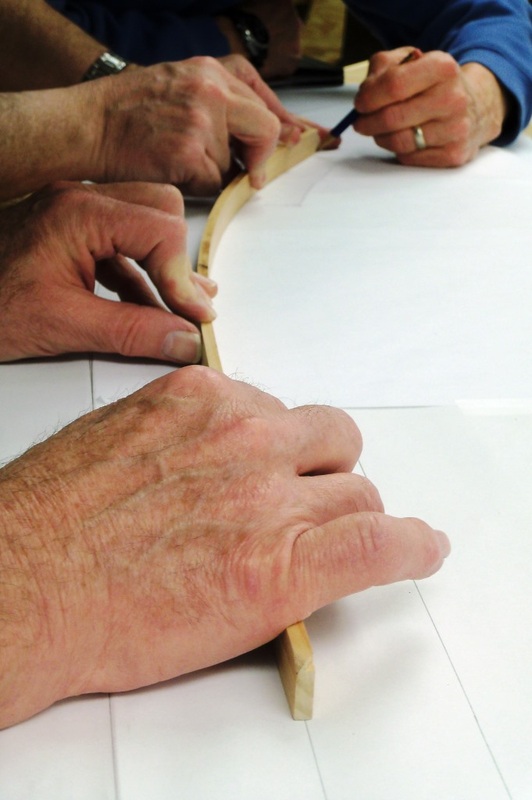

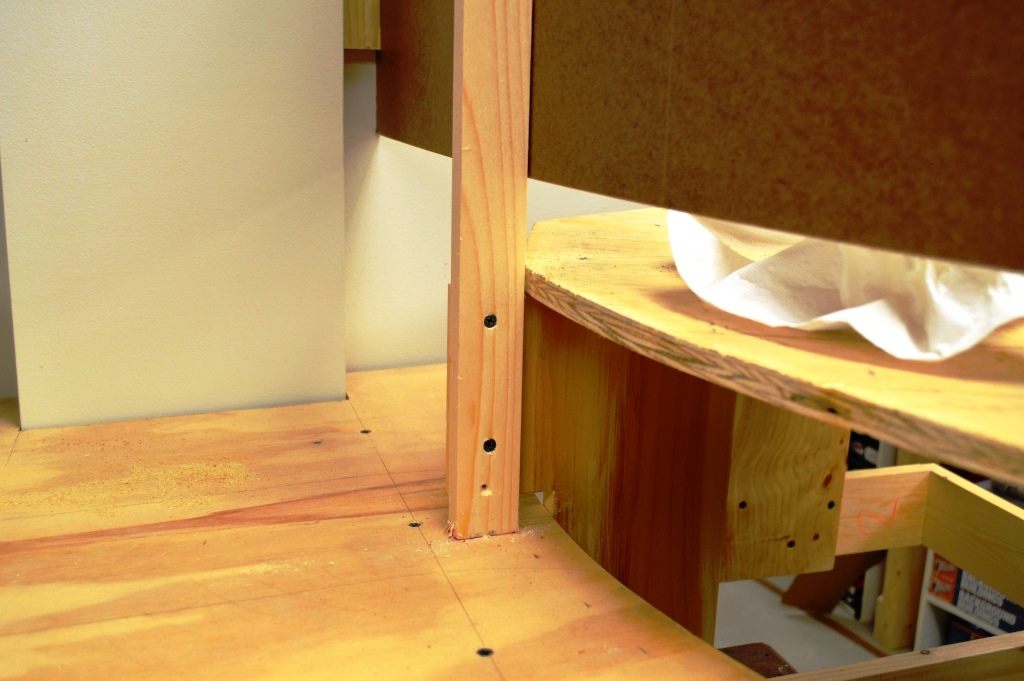

Here is a close up of a lap joint. We used the amber Gorilla Glue on these joints, clamping the two pieces together until they dried (the Gorilla Glue expands as it dries and if not clamped would push the pieces apart). The lap joints eliminated the need for "splints" under each joint and allowed us to keep the helix slope as flat as possible and minimize the rise of each revolution. We used blocks of 1' x 4" as risers, positioned on the inside and outside edge of the helix segments.

2007

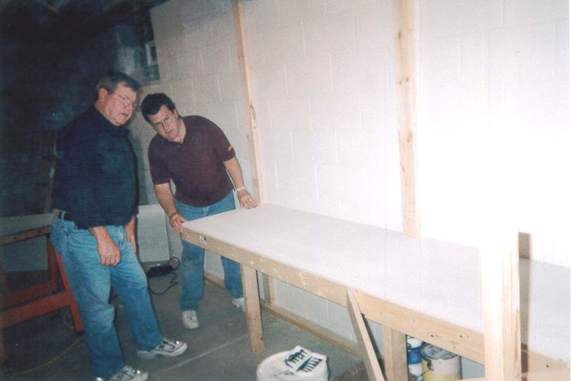

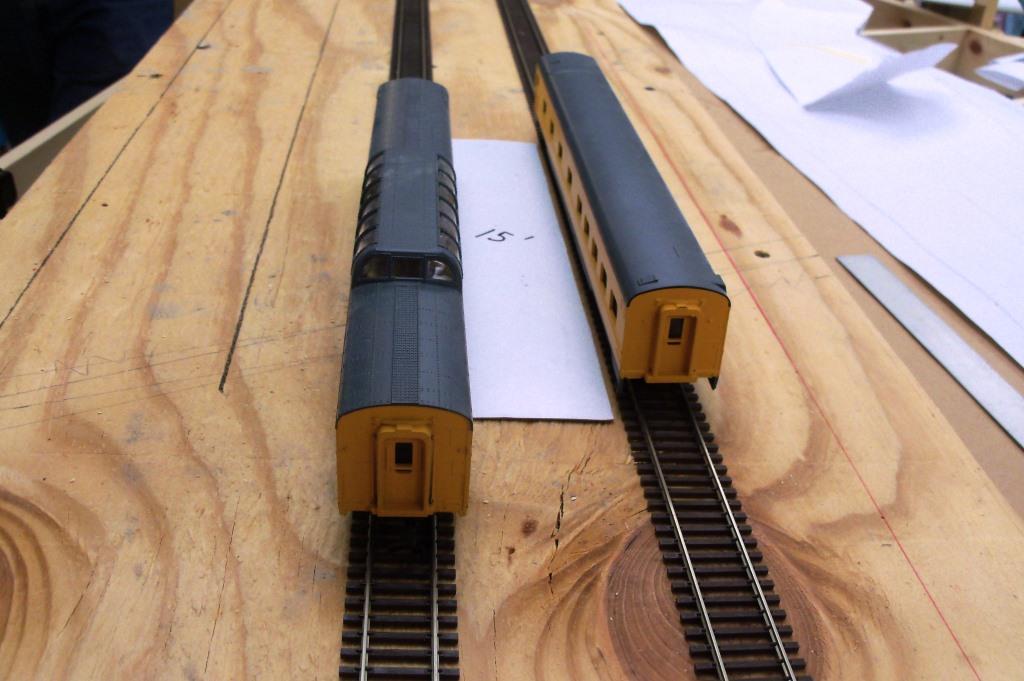

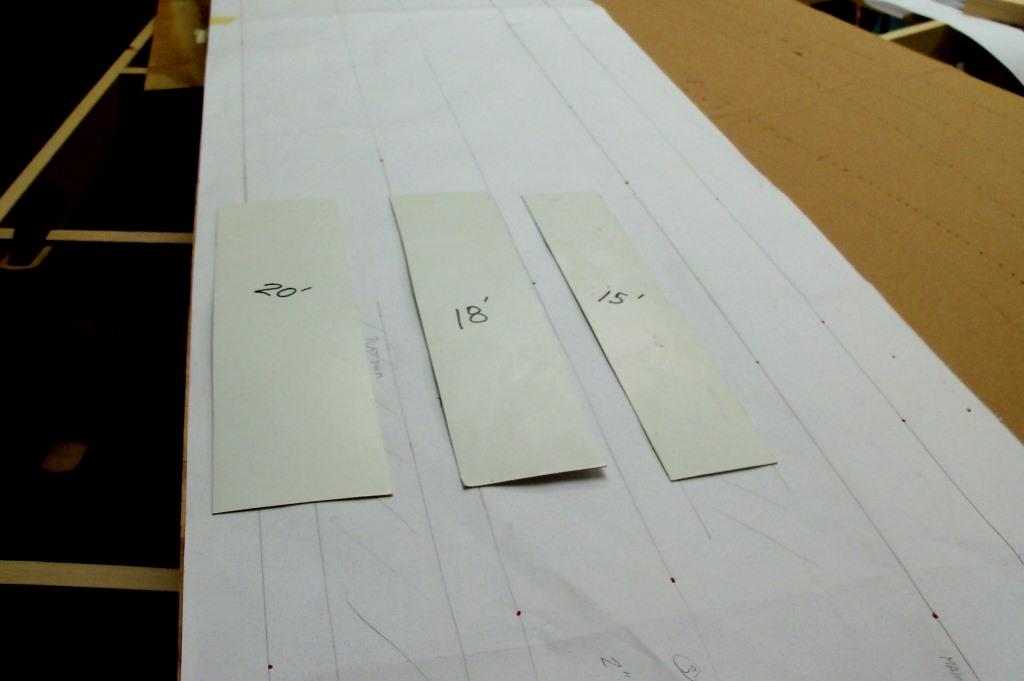

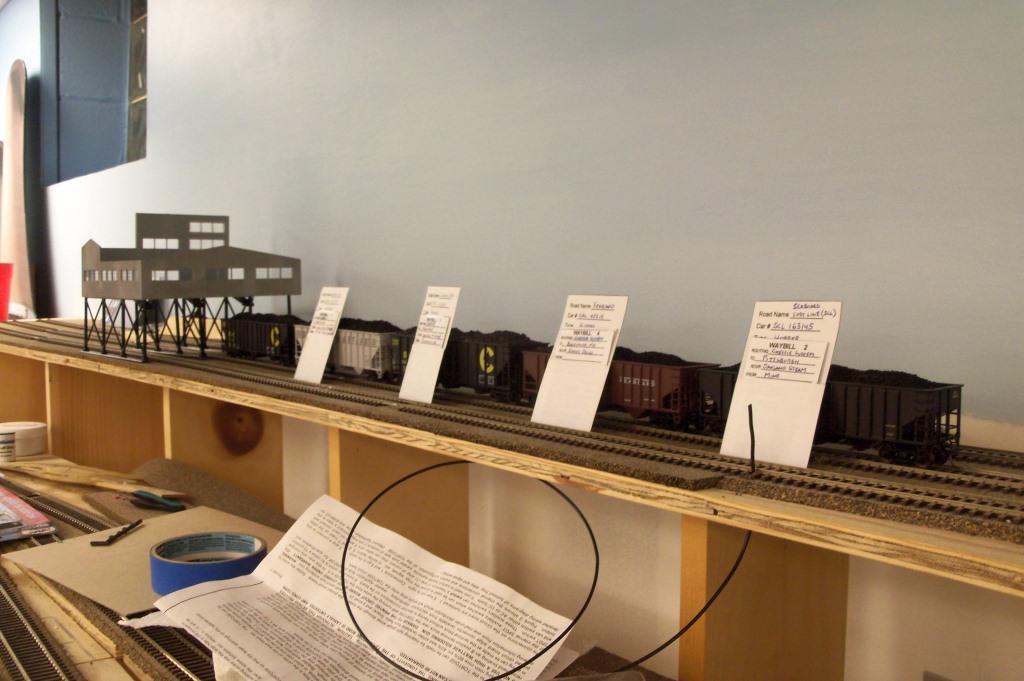

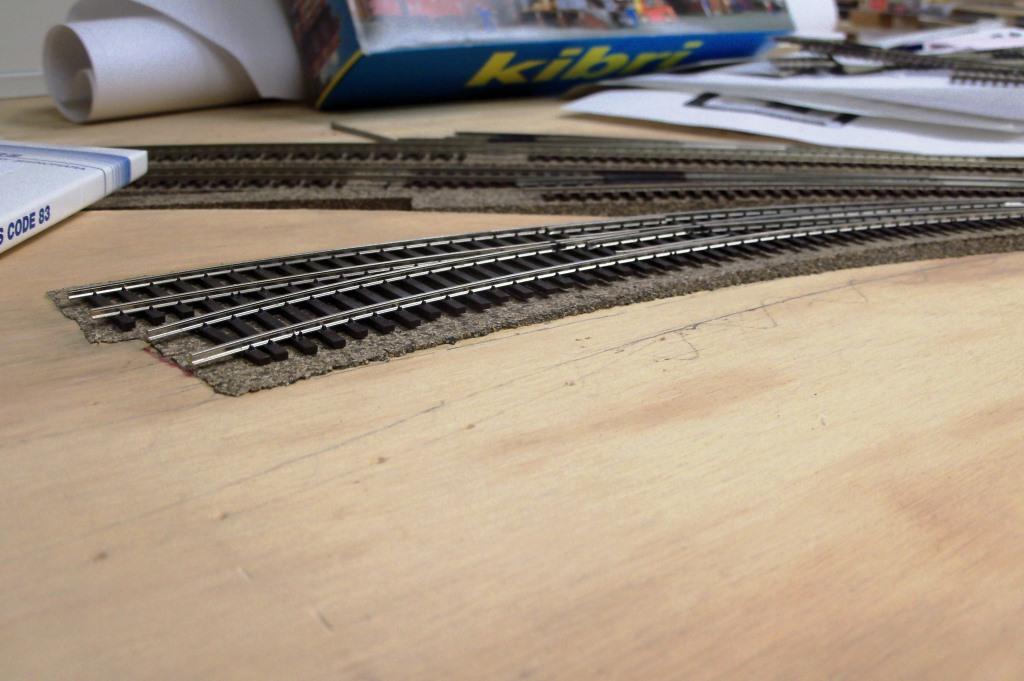

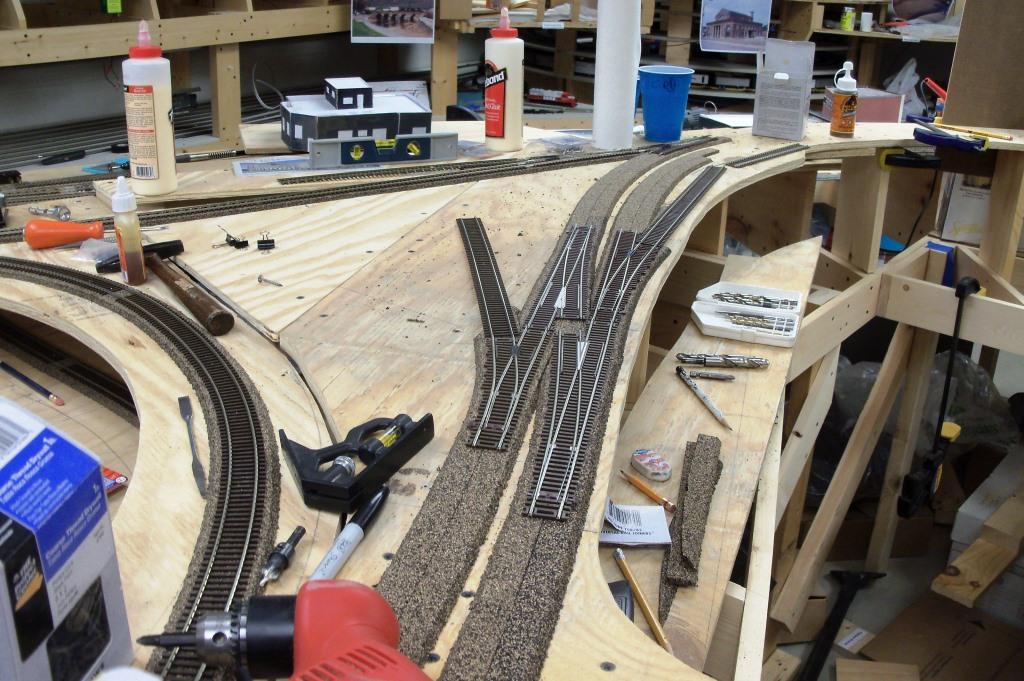

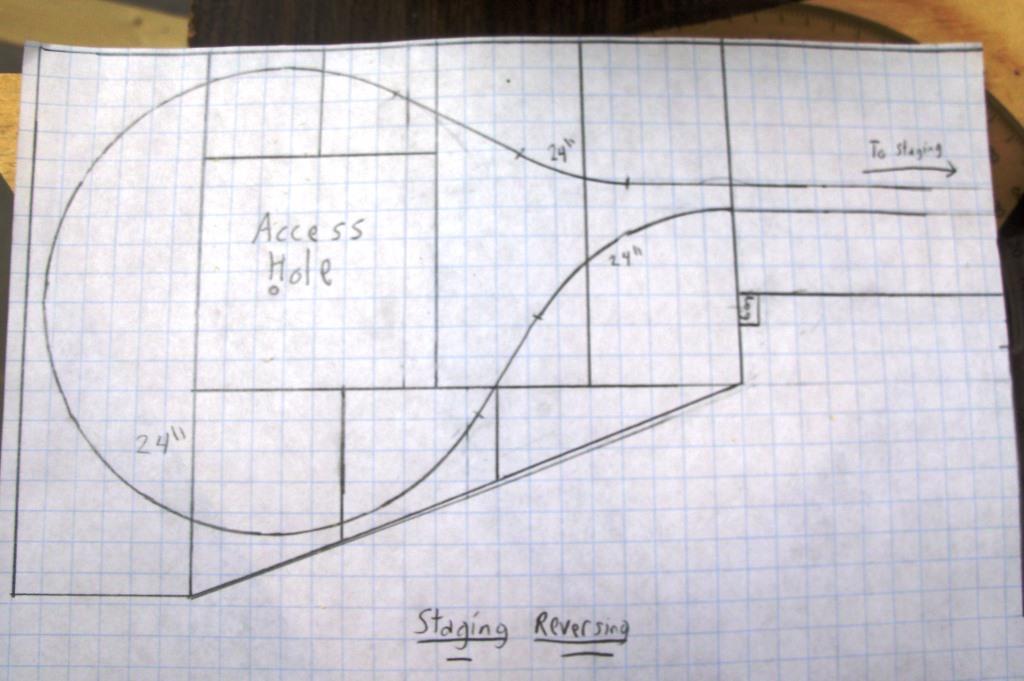

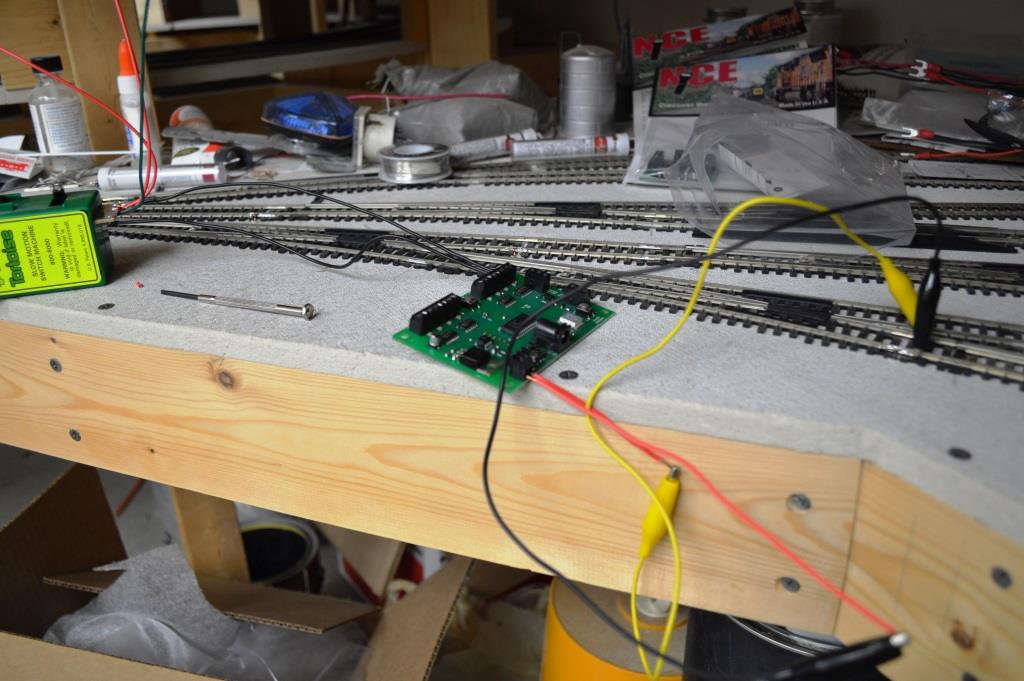

During 2007 the Chessie and Eastbound Conrail staging yards were built and the track was laid. The Eastbound Conrail staging yard is a 6 track double ended yard. The Chessie staging yard has 7 tracks and is a shorter stub ended yard.

2008

In 2008 the benchwork and track for the Chessie Johnstown yard and a few industries were completed. At first it was done on foam but we soon realized plywood would work a lot better and we relaid all the track and turnouts. Not much was done because the drop ceiling had to be put in.

2009

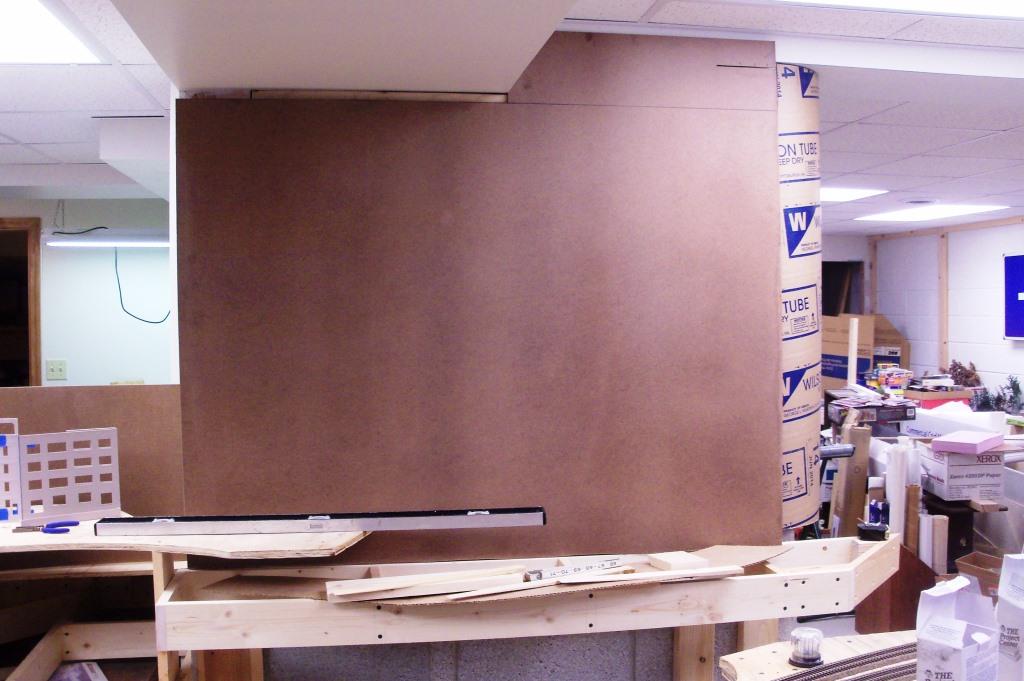

In 2009 the drop ceiling was put in for the older room. We also started planning the power plant and mine. We also put up the masonite for the backdrop. The joints between sheets of masonite were taped and mudded just like drywall joints.

2010

In 2010 Andy had to finish the new room by putting waterproofing sealer on the foundation walls, and installing drywall at the far end against the stairs. But we did manage to extend the mainline to Latrobe and paint the backdrop.

2011

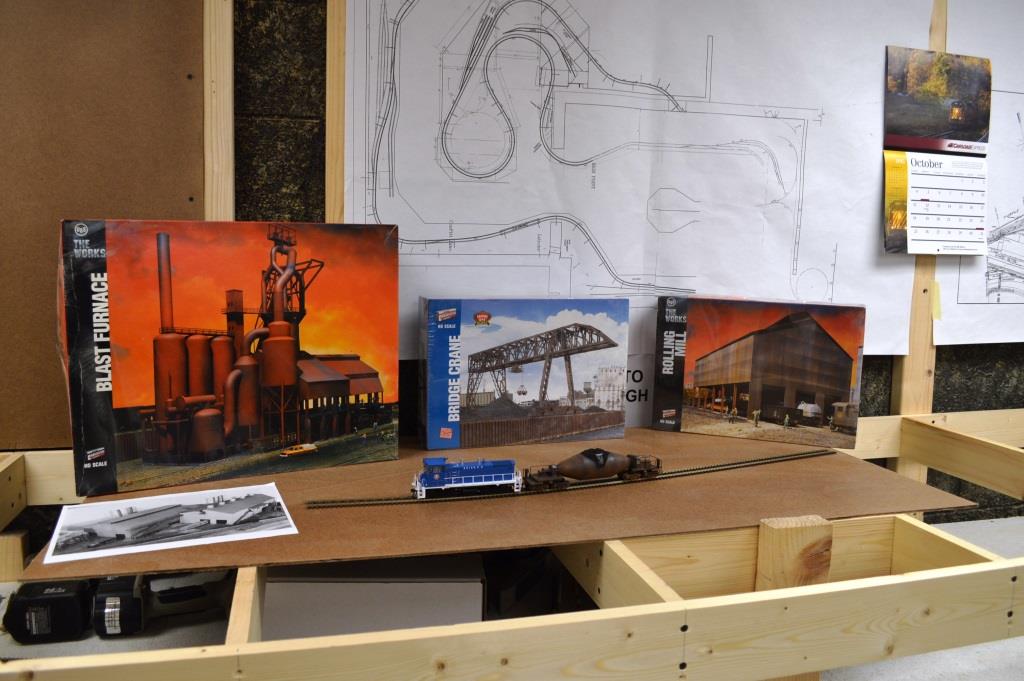

During 2011 the Westbound Conrail staging yard was built. The track was put in for Cambria Iron Works in Johnstown as well. Also the cooling towers were made.

2012

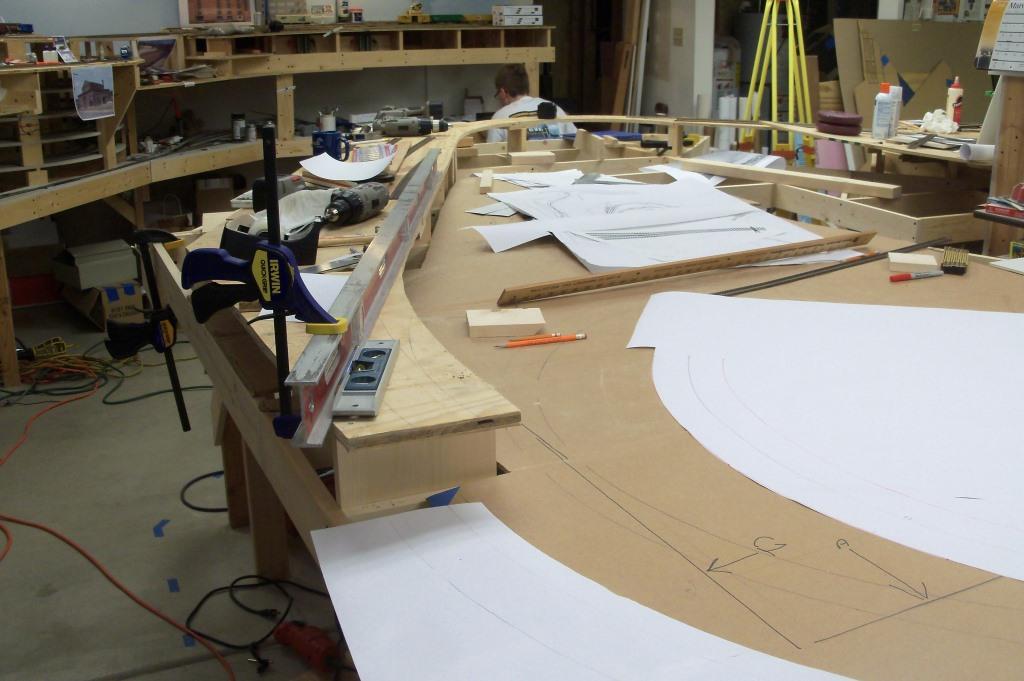

During 2012 we began to work East from Island Avenue.

10/5/2012

10/26/2012

11/2/2012

2013

1/4/2013

2/1/2013

3/1/2013

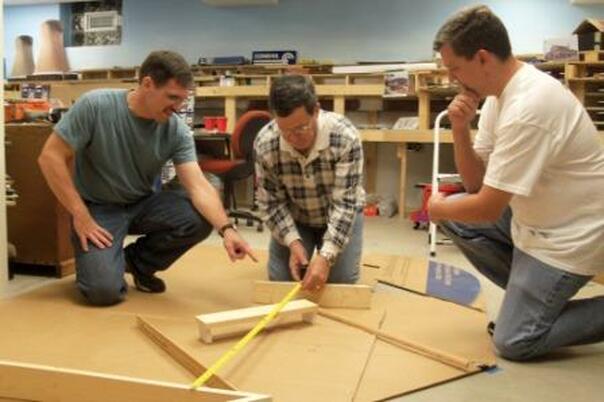

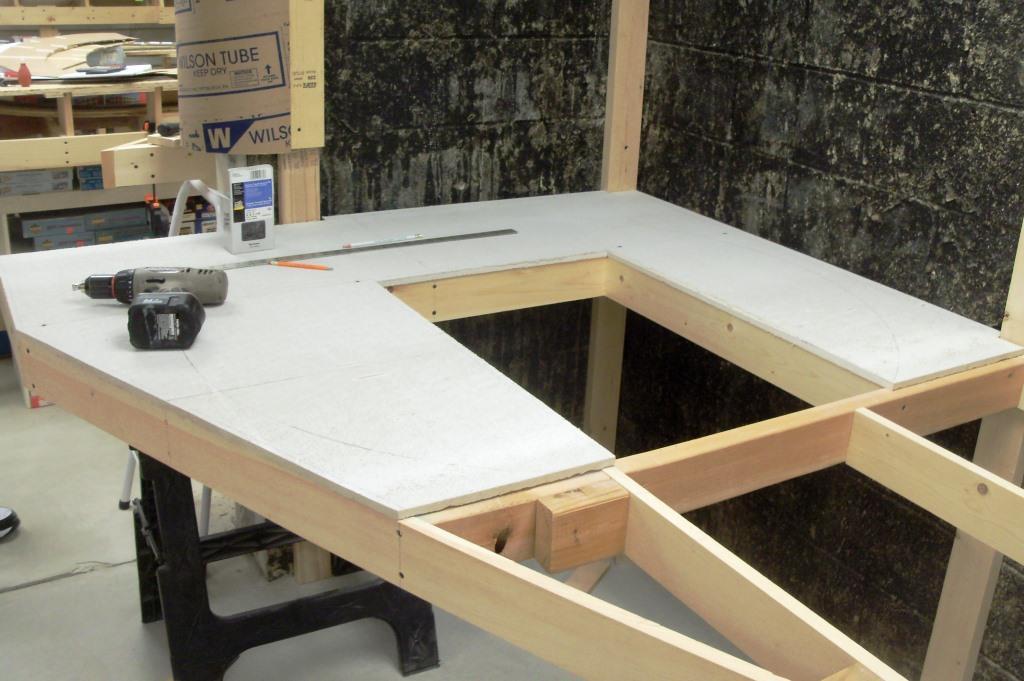

We had a light work crew Friday - Jerry, Charlie & Andy, but what we accomplished was done well and sets us up for the next work session. Here Charlie and Jerry add a diagonal brace to the corner of the benchwork. They also leveled the last two sections of benchwork, and cut and attached permanent legs. (This area will be Shadyside/East Liberty on the completed layout.) Charlie reports that Jerry is a great teacher of carpentry skills.

Meanwhile, Andy made adjustments to the plywoodf sub-grade that will carry the mainline through the foundation wall from staging to Island Avenue Yard. 3/8" was trimmed from the top of the benchwork, which allowed for a drop off to exactly match the cork roadbed thickness. Howard suggested this so the track can be spiked to the cork rather than plywood, which will be much easier in the "tunnel." Note the siderails which were added last session; they took the warp out of the plywood but will also will help protect rolling stock in the event of a derailment.

11/22/2013

We pretty much took the summer off to chase and photograph real trains and Heritage locomotives, but now the lawnmower is put to bed for the winter and it is dark at 5 pm, so it's time to get back to layout construction. Jerry and Bob were available on short notice and came over Friday night to help.

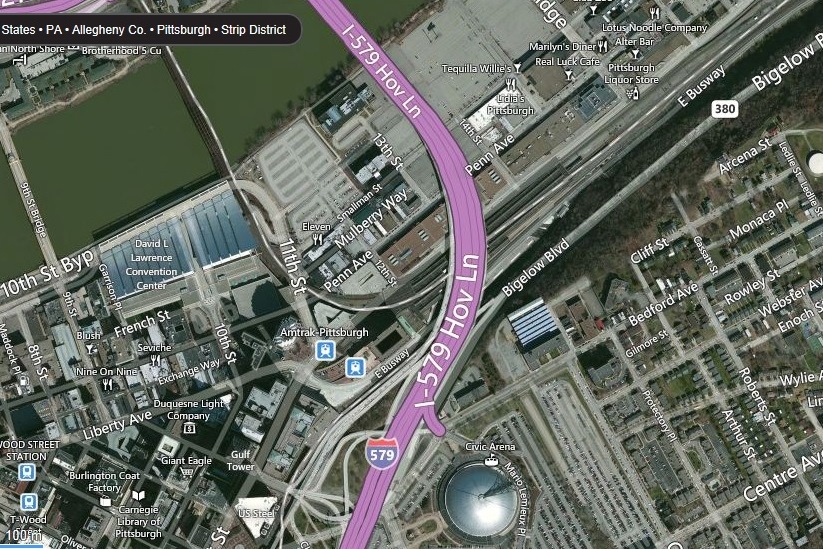

Around the corner, it was time to finalize the alignment of the Fort Wayne Bridge, which in the prototype carries the main line across the Allegheny River. We wanted to include the 16th Street Bridge (recently renamed for author and Pittsburgh native David McCullough) in the background as this would have been the next bridge upstream in our time era. It is possible to photograph this bridge from Interstate 579 on the Veteran's Memorial Bridge, but our camera does not have a wide angle lens. Alas, my brother John was in town last weekend and he is a skilled photographer with a nice collection of lenses. He readily agreed to try and get the shot and the end result is terrific (see below). We plan to have this professionally printed and adhered to foamcore board as we did with the cooling towers for Conemaugh Generating Station. The key will be to get the print to the right size to match the river banks.

January - February 2014

Although it has been quite a while since we posted a progress report, we have had a half dozen work sessions this winter and are moving forward. Here are some recent photos.

3/7/2014

4/4/2014

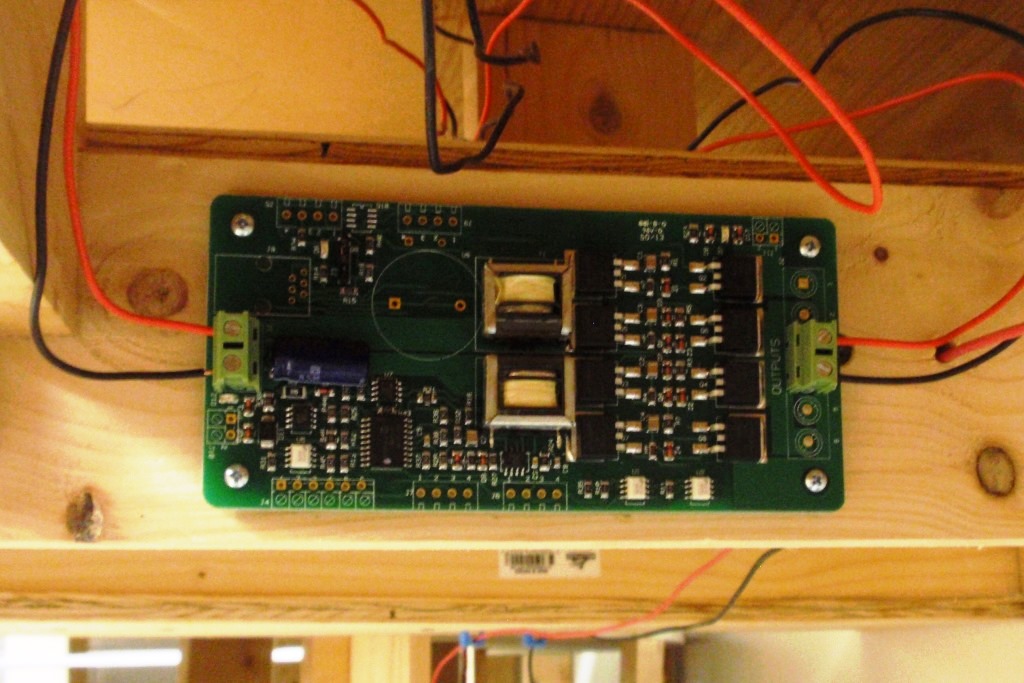

After installing the reversing circuit, a Chessie SD40-2 made the first run over the Johnstown wye.

September 2014

After taking the summer off, we are getting busy working on the layout again. Here are a few recent photos.

October 2014

With the NMRA meeting and open house fast approaching, we hustled to try and get as much done as possible. We had work sessions on three consecutive nights and worked our tails off. Thanks guys!

November 2014

The progress continues...

Through September 2015

I have been reminded that there have been no progress updates for eight months, so allow me to fill you in. We accomplished some progress last spring, and after taking the summer off, are again back in a routine of working on the layout. Here is what we have gotten done so far in 2015.

~ Andy

~ Andy

October 2015

With another NMRA meeting and open house this month, we really made a push to get work done on 10/2/2015. Here are some photos.

December 2015

And that pretty much wraps up 2015. We are going to start a new page for our second decade of progress, which we will arrange like a blog page, putting the most recent entries at the top. This will eliminate the need to scroll to the bottom to check for updates.